Liposomal Vitamin C Test Results / Bioavailability

Auf dieser Seite veröffentlichen wir unsere Garantie und Testergebnisse betreffend der Partikelgröße die maßgebend die Bioverfügbarkeit des liposomales Vitamin C’s ausmachen. Hier können Sie sehen, das wir ein wirkliches liposomales Produkt herstellen, was die Messergebnisse deutlich zeigen. Nur ein wirklich liposomales Produkt mit der richtigen Partikelgröße vermag die vielfach positiv beschriebene Wirkung zu erzielen. Die Bioverfügbarkeit steht für die Wirksamkeit des liposomalen Produktes und damit wieder für Qualität.

Detaillierte Untersuchungsergebnisse

Diese Untersuchungen werden von uns stetig durchgeführt um die Qualität resp. Bioverfügbarkeit immer sicherzustellen. Wir wollen dem Kunden die höchstmögliche Qualität anbieten, denn wir sind überzeugt davon, dass wir nur so auf dem Markt bestehen können (was sich in den nun 8 Jahren seit Markteinführung klar gezeigt hat).

Darum betreiben wir auch diesen Aufwand und sind mit unseren Produkten erst zufrieden, wenn diese alle unseren hoch gesteckten Normen auch voll erfüllen.

Weiter ist es auch so, das unsere, zum Teil schwer kranken Kunden (Krebs- und Autoimmunkranke) auf die Wirksamkeit unserer Produkte zählen, und dieser Verantwortung müssen wir in jedem Falle gerecht werden. Da es sich hier nicht um “irgendwelches” Vitamin C-Getränk handelt, das aus reinen Profitgründen an “irgendwelche” Verbraucher verkauft werden, fühlen wir uns verpflichtet, nur die beste und wirkungsvollste Qualität zu produzieren.

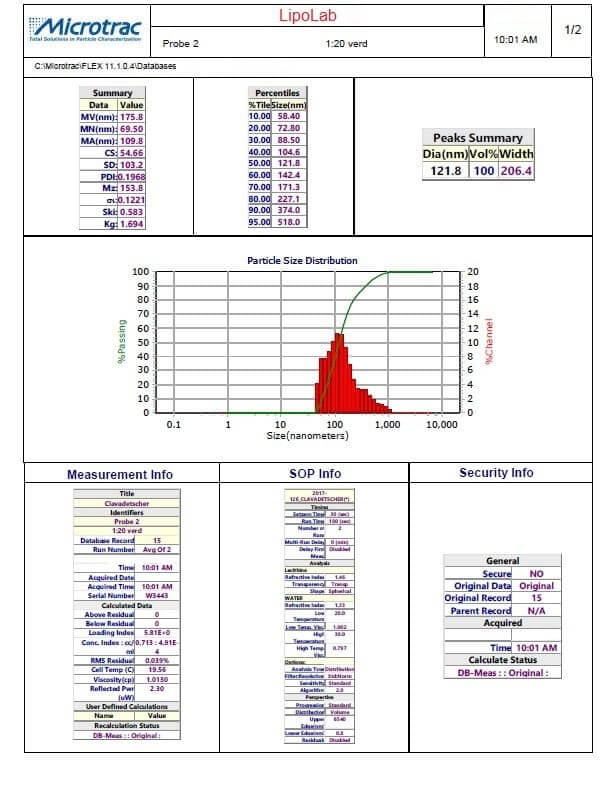

Hier nun die detaillierten Messergebnisse von Microtrac:

Die Schwierigkeiten bei der Partikelgröße

In order to produce an effective liposomal vitamin C, the right particle size is required, which in this case has to be very small. It is relatively easy to work on the micro scale and produce particles of this size. But to get into the smaller nano range is much more complex and you have to be very careful that these particles don’t get too small. Because below 20 nanometers the surface tension of the particles increases and it can happen that these particles burst because of this tension. That would then make the product worthless and the effectiveness, i.e. bioavailability, would no longer exist.

Darum müssen diese Liposomen die richtige und für unseren Körper richtige Größe aufweisen damit der volle Nutzen da ist. Wirksames liposomales Vitamin C fällt und steht also mit der richtigen Partikelgröße.

Wie erreicht man diese Partikelgröße?

As already mentioned, this procedure is not easy and requires a lot of energy. But where a lot of energy is needed, heat is also generated. However, this heat damages the lipid and destroys it. Therefore, effective cooling must be ensured during processing. This is done with a cooling coil, whereby the medium is repeatedly treated for a short time up to a temperature of 29 degrees and then cooled down again to around 4 degrees. Numerous such passes are important until the desired particle size is achieved.

Ultraschallbeschallung

With very powerful ultrasonic devices, which emit high energy (ultrasonic) on the smallest diameter, the particles are continuously crushed in several passes. These ultrasonic waves, which hit the medium with over 3000 watts of power, shred the larger particles until they reach the right size after a few repetitions. As already mentioned, heat is generated during this process and with these energies, which must be cooled again and again. The liposome (lipid) does not tolerate heat and is therefore easily destroyed. So of course this has to be prevented.

At the tip of the power transmission, which is made of titanium (which is only about 3 centimeters in diameter), speeds of over 1000 km/h are achieved in operation. These cavitation velocities, which form when bubbles implode (also called bubble implosion), are called

Die Energien die bei diesem Pzrozess frei werden, sind sogar im Stande Titanium zu durchlöchern wie man auf einem Bild auf unserer Seite sehen kann.

Therefore, the production of liposomal vitamin C is not very easy and in order to produce a real liposomal product, it requires quite a large financial effort.

Die Frage ob man liposomales Vitamin C selbst herstellen kann, kann man eigentlich mit Ja beantworten, aber es bedarf des richtigen Equipments. Für den Hausgebrauch aber ist das unmöglich, da ein solches Produkt dann astronomisch teuer zu stehen kommen würde.